Recognizing the Capability of Membrane Switches Over for Interface Tools

The performance of membrane switches represents a considerable innovation in user interface style, combining performance with aesthetic versatility. As industries significantly prioritize customer experience, recognizing the nuances of membrane layer switch technology becomes vital.

What Are Membrane Layer Buttons?

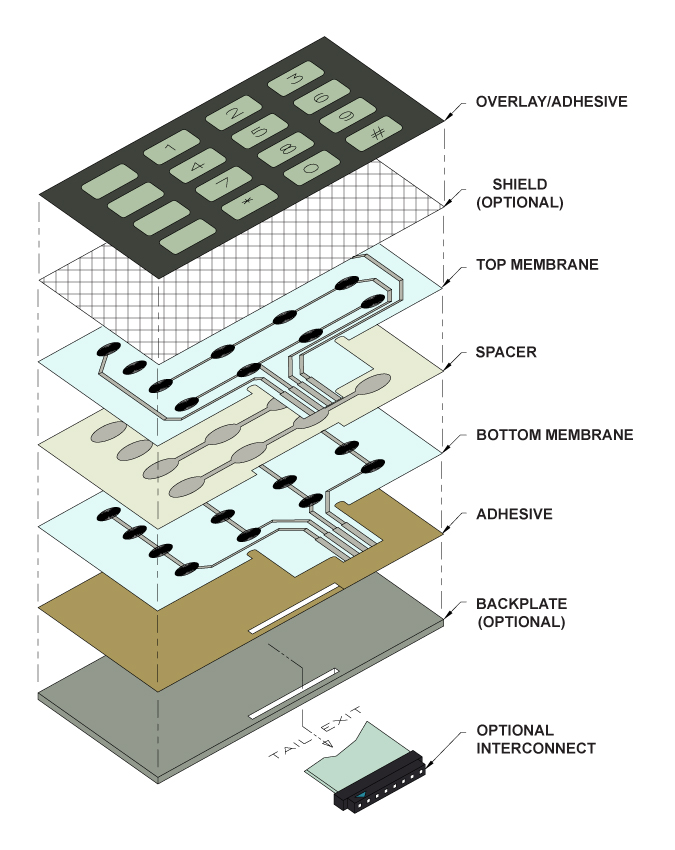

Membrane layer buttons are innovative user interface gadgets that help with customer communication with electronic devices. These flexible parts contain numerous layers, consisting of a graphic overlay, spacer, and a printed circuit layer. The style enables for a seamless combination right into numerous digital tools, boosting both the aesthetic and practical facets of customer interfaces.

Membrane layer buttons are frequently utilized in a broad array of applications, from household home appliances to industrial equipment and clinical devices. Their building and construction commonly includes a slim account, making them a suitable selection for small styles. The tactile feedback offered by these switches can be engineered to meet specific individual preferences, making sure reliable interaction between the customer and the tool.

Sturdiness is an additional substantial benefit of membrane layer buttons, as they are resistant to dust, dampness, and chemicals, which improves their life expectancy sought after atmospheres. In addition, these buttons can be personalized in regards to shape, size, and graphic style, enabling branding and user-specific features. On the whole, membrane layer changes represent a useful remedy for enhancing individual experience in electronic tools, combining performance with visual allure in a reliable fashion.

Just How Membrane Changes Job

Operating on an uncomplicated principle, membrane switches over make use of a split building and construction to sign up individual input efficiently. Each switch contains numerous layers, including a printed circuit layer, a spacer layer, and a top visuals layer, which are developed to work together seamlessly. When a customer presses the leading layer, it presses the spacer layer, bringing the conductive aspects of the circuit layer right into contact with each other.

This call creates a shut circuit, signifying the tool to implement a particular function. The design permits for numerous setups, consisting of responsive responses, which can enhance the user experience by giving a physical experience upon activation. The products used in membrane layer buttons typically include flexible substratums, such as polyester or polycarbonate, which guarantee durability and resilience versus deterioration.

Trick Benefits of Membrane Layer Switches

An additional considerable benefit is their density. Membrane layer buttons are slim and lightweight, which allows suppliers to conserve space in their gadgets without compromising performance. This attribute is especially useful in applications where weight and volume are crucial factors to consider.

Furthermore, membrane layer switches are resistant to dirt, wetness, and chemicals, boosting their durability. This strength expands their life expectancy and minimizes the requirement for frequent substitutes, resulting in cost financial savings with time.

Additionally, the responsive comments given by membrane buttons can be optimized to boost customer communication. They can include features such as raised switches or audible clicks, enhancing functionality and user experience.

Applications Across Industries

User user interface devices using membrane layer buttons prevail in a broad selection of sectors, showcasing their versatility and capability. Membrane Switch. In the medical industry, membrane buttons are important to gadgets such as diagnostic equipment and patient our website monitoring systems, where their longevity this article and ease of cleaning are vital for preserving hygiene criteria. Likewise, in the automotive sector, these switches are used in control panel controls and infomercial systems, providing a smooth and contemporary user interface for customers.

Additionally, the customer electronic devices sector gain from membrane layer buttons in home appliances and portable tools, where compact design and easy to use user interfaces boost individual experience. Industrial applications additionally leverage membrane layer switches over for control board in machinery and automation systems, highlighting their effectiveness and resistance to severe atmospheres.

In the aerospace and defense sectors, membrane layer buttons are used in cabin controls and devices, where integrity and efficiency under extreme conditions are extremely important. Furthermore, the pc gaming industry significantly integrates membrane switches in controllers and game machines, contributing to an appealing customer experience. Generally, the adaptability of membrane switches allows their widespread use throughout numerous fields, underscoring their importance in contemporary user interface style.

Future Patterns in Membrane Switch Over Modern Technology

Additionally, the usage of advanced products, such as polycarbonate and polyester films, is expected to rise, giving improved toughness and resistance to ecological stress factors. These materials contribute to the general longevity of membrane layer switches, making them suitable for harsher commercial applications.

Furthermore, the unification of smart modern technology, consisting of IoT connection, will certainly allow membrane buttons to communicate with other tools and systems, promoting a much more interactive individual experience. This fad aligns with the growing demand for wise tools throughout various fields, from medical care to consumer electronics.

Lastly, customization alternatives are prepared for to increase, allowing makers to develop bespoke options customized to details user requirements and preferences. These developments will position membrane layer buttons as vital elements in the evolution of interface technology.

Verdict

In verdict, membrane layer changes represent a crucial innovation in individual interface technology, supplying a trusted and flexible remedy for varied electronic applications. As advancements in product scientific research and touch noticing modern technologies proceed, the functionality and applicability of membrane layer buttons are anticipated to increase, strengthening their importance in modern-day electronic devices.